Network Upgrade for Aggregate and Quarry Facilities

Private Cellular Networking

Overview

Industrial Networking Solutions works with an aggregate company that is a full-service construction supply and material operation employing more than one thousand people with dozens of facilities located across the United States.

Challenge

The aggregate company had a quarry with an aging network that was isolated and not integrated into their business network. The network had reached its practical limits and could not be expanded reliably using the existing infrastructure.

The legacy network and software limitations made it difficult for the quarry to add new intelligent edge devices, get real-time information and collect or historize data. The limited data the quarry operator received was up to seven days behind because the existing network and data entry systems could not provide real-time data. This delay resulted in a big gap between scheduling and the ability to plan more efficiently, as well as the ability to respond to customer requests quickly.

“If you visit our sites, you see that several problems exist. One of those is our silos of data. We may have PLCs working on the site for ten years, but what lives inside of that PLC was not used. As a result, we couldn’t pull the information and learn from our mistakes,” said the customer.

Additionally, SCADA data was only monitored and collected by a single operator at each quarry into offline spreadsheets, making it difficult to analyze or act on the data. Finally, older SCADA client licensing models and architectures prevented them from using critical process data globally across multiple systems and users.

Recognizing the need for an expert in industrial networks and Ignition software, the customer chose Industrial Networking Solutions (INS) to help them update their quarry network, including Layer infrastructure and a SCADA software system.

Solution

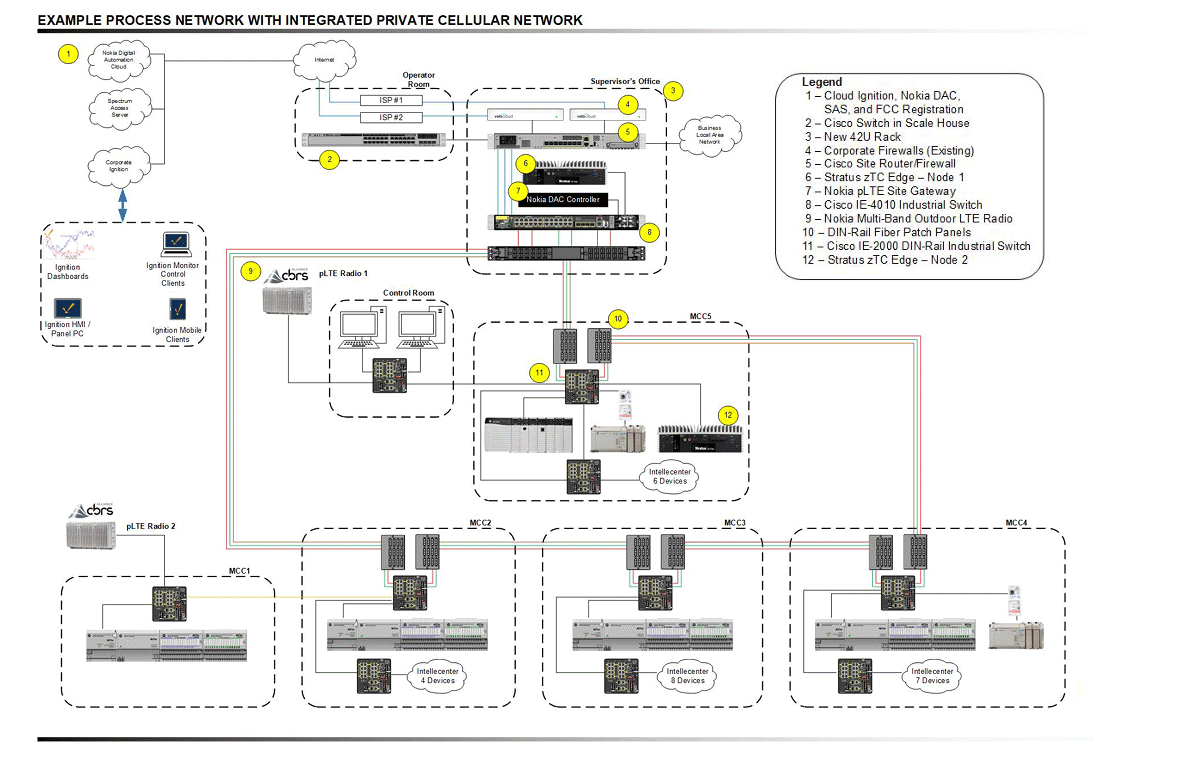

The first step was for INS to conduct a site survey to analyze the existing network and SCADA infrastructure and meet with stakeholders to establish current and future system functional needs. Through the meetings, INS realized the network architecture needed to include enough bandwidth to address additional back-office integration and cybersecurity traffic needs. INS deployed a backbone Network using Singlemode Fiber Optic and Cat 6 Copper cabling, connectors and cabinets to ensure consistent data transfer.

To meet the customer’s current and future needs, INS used a Cisco validated design backbone, a fixed asset network and a highly secure Nokia Private Cellular Network to connect mobile assets throughout the quarry and provide mobile workers with real-time connectivity into the plant operations and reporting systems. Cisco Validated Designs are tested and validated reference architectures that provide the core network foundation to help reduce risk and successfully deploy today’s top automation platforms and Industrial IoT solutions.

The customer chose Inductive Automation’s Ignition for their control system’s Historian, reporting and back-office connectivity needs. INS architected a combination of edge IoT and cloud technologies, hardware and software. Leveraging the Ignition platform to integrate data from the plant to their Azure cloud-hosted enterprise system, INS combined Ignition’s Vision and Perspective clients for production monitoring, historical information and data integration to their business systems. Ultimately, the new network and software allowed the business to identify and react to downtime root causes, eliminated manual data entry labor and errors by streamlining the data straight to the data warehouse and cloud, provided tighter business integration and gave maintenance visibility into quarry operations.

Results

The customer now has a network and software infrastructure at the quarry and corporate level that lowers workforce costs and allows real-time inventory and performance monitoring, better insight into downtime and production issues. Additionally, the new data permits them to develop new Key Performance Indicators (KPI’s) that reduce downtime, improve efficiencies and collaborate better as a whole.

The customer values working with INS because of their attention to detail and results. Due to the increased efficiency and real-time visibility the initial rollout provided, they have tasked INS to deploy the exact solution to their other quarries and expand upon the business systems integration.

Case Study Partners

Nokia

Cisco

Inductive Automation