Optimizing Efficiency with Ruggedized Hardware

Moxa Industrial Networking Hardware

Overview

Goodnight Midstream, founded in 2011, specializes in saltwater management for oil and gas operators. They provide long-term produced water disposal services, understanding the impact of water handling on operational reliability. Initially starting with three saltwater disposal wells and a two-mile pipeline in the Bakken, they have grown to operate over 450 miles of gathering lines connected to more than 50 saltwater disposal wells across the Williston Basin, Permian Basin, and Eagle Ford Shale, continuously expanding their operations.

Oil and gas operators need water management services because the extraction process generates large volumes of produced water. Managing this water is crucial to ensure operational efficiency, environmental compliance, and cost-effectiveness. Proper water management reduces the risk of spills, contamination, and regulatory fines, while also allowing operators to focus on their core activities. Services like water transportation, treatment, and disposal help maintain the sustainability and safety of oil and gas operations.

Goodnight Midstream’s operations provide safe, efficient water management systems meeting stringent regulatory and environmental standards. They offer pipeline solutions which reduce greenhouse gas emissions compared to truck disposal operations and protect freshwater resources. Their operations help oil and gas operators develop resources sustainably, contributing to cleaner oilfields in the US shale basins. By leveraging modern technology and geologically sustainable reservoirs, they ensure environmental protection and operational reliability.

Industry Challenge

Operating in harsh and remote oilfield environments, Goodnight Midstream requires networking solutions which can withstand extreme conditions while ensuring reliable process control and data management. The primary objectives were to:

- Enable real-time visualization and monitoring of water management processes.

- Ensure seamless data transmission from remote and distributed sites.

- Provide power to various network devices, including video cameras, over Ethernet cable.

Solution

Industrial Networking Solutions (INS) provided a comprehensive suite of industrial-grade networking products designed to meet the rugged demands of the project. The key components of the solution included:

- Ignition® SCADA Software by Inductive Automation:

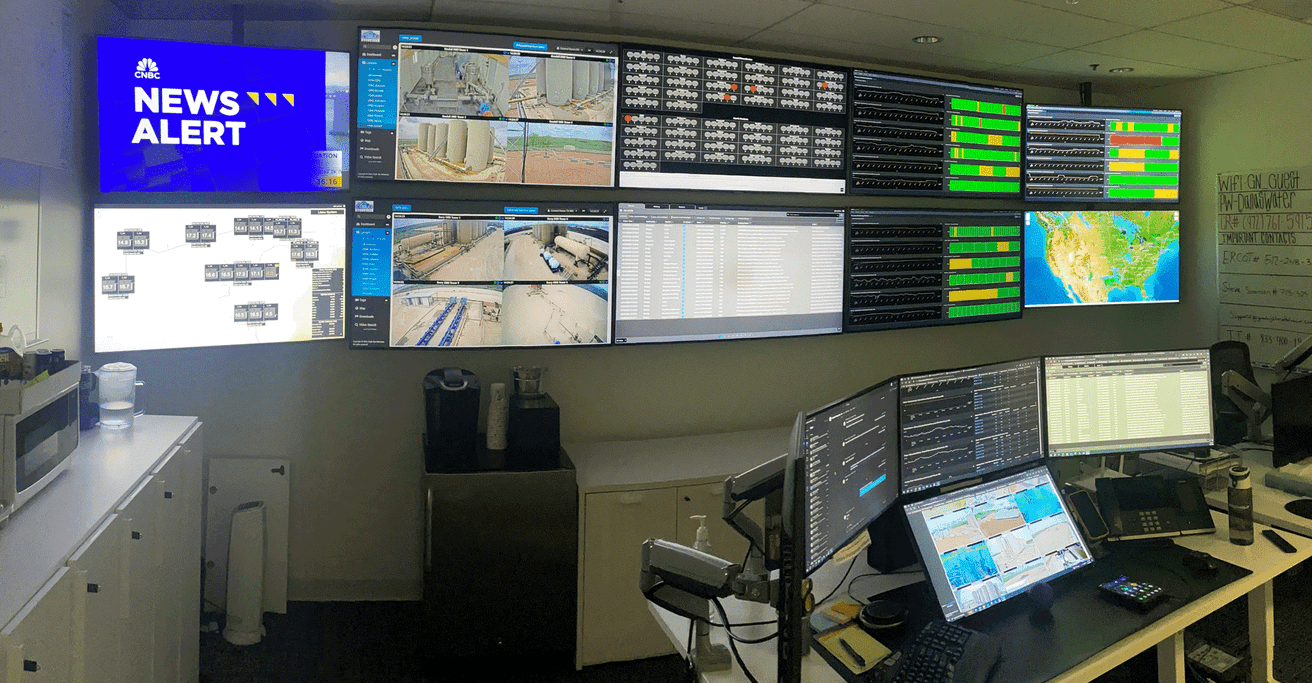

- This innovative SCADA software was deployed to handle process control and data management efficiently. It facilitated real-time monitoring and control, offering robust visualization of the entire water management process.

- AIG-501 Series Programmable IIoT Gateways by Moxa:

- These gateways were crucial for connecting remote and unmanned sites. Designed for harsh operating environments, the AIG-501 series ensured reliable data transmission and integration across the network.

- INJ-24 Series PoE Injectors by Moxa:

- To power video cameras and other devices, INJ-24 series PoE injectors were used. These devices combined power and data over a single Ethernet cable, enabling non-PoE power source equipment to supply power to powered devices. This setup was essential for transmitting video feeds to the on-site control room, ensuring constant surveillance and monitoring.

Implementation

INS and Goodnight Midstream collaborated closely to design and deploy an industrial-grade network. The implementation involved:

- Setting up the Ignition® SCADA system for comprehensive process visualization.

- Installing AIG-501 gateways to ensure reliable communication from remote locations.

- Utilizing INJ-24 PoE injectors to streamline power distribution and data transmission.

This integrated solution provided Goodnight Midstream with a resilient network capable of enduring harsh environmental challenges. Seamless connectivity and power management significantly enhanced operational efficiency and data accuracy.

Speaking on the project hardware one Goodnight networking engineer stated, “Leveraging Moxa equipment has been a key component in increasing information systems uptime, increasing data resolution, and creating cost effective solutions for common connectivity challenges. Reliable, high-resolution data is helping pave the way for our journey from automation to autonomy.”

Results

The deployment of industrial networking solutions resulted in:

- Improved Process Visibility: Real-time data and process control enabled better decision-making and operational oversight.

- Enhanced Reliability: Rugged networking components ensured uninterrupted operation in harsh environments.

- Efficient Power Management: PoE injectors simplified power distribution, reducing the need for additional cabling and infrastructure.

Conclusion

By partnering with INS and implementing Moxa rugged networking hardware, Goodnight Midstream successfully established a robust and efficient network infrastructure. While INS did not provide OT Services for this solution, Goodnight Midstream recognized the importance of working with a value-added reseller. INS provided expertise, customization, and support tailored to Goodnight Midstream’s specific needs, offering pre-sales consulting, integration recommendations, and post-sales support. This collaboration exemplifies how tailored networking solutions can address the unique challenges of demanding environments, ultimately leading to improved operational performance and reliability.

Case Study Partners

Goodnight Midstream

Moxa